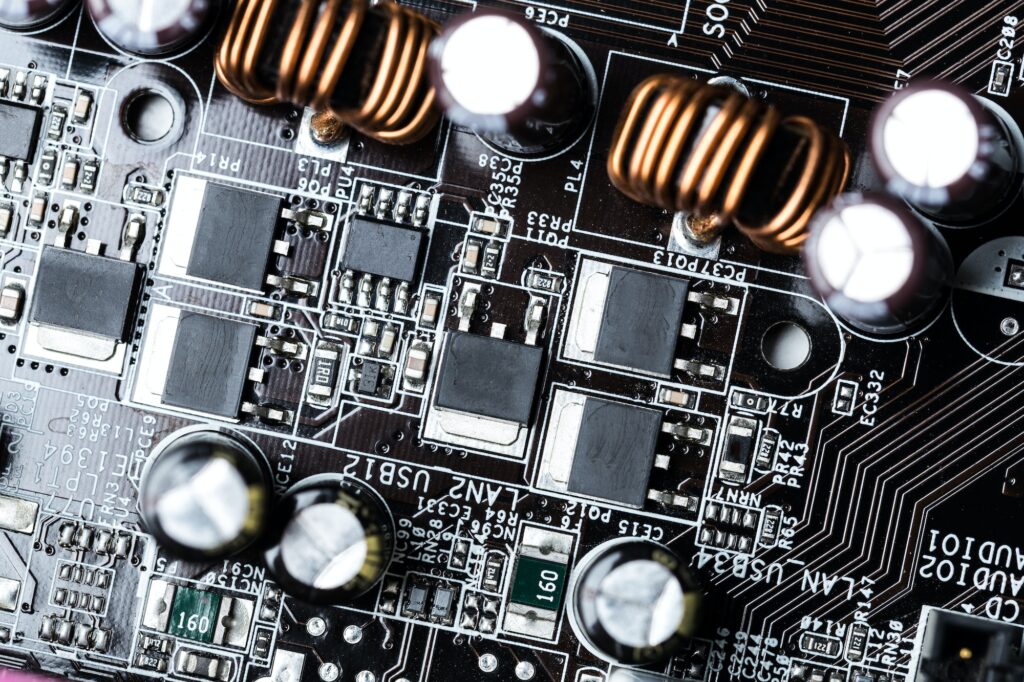

HARDWARE ENGINEERING

Using advanced technology to meet your hardware manufacturing needs

Our team is dedicated to going above and beyond expectations at every step of your hardware engineering process and is available online 24/7 to serve our clients across the globe.

A brief overview of our service offering in this category includes:

PCB Fabrication

This refers to our full feature printed circuit board manufacturing services. CPS Tech provides most substrate materials including FR4, Aluminum and Rogers. Our Standard PCB only uses FR4 based PCB.

CPS Tech will assist you by proofing your designs before you start full-scale production to help reduce your design cost and quickly turn your design into reality. Depending on your project requirements, CPS Tech can customize your prototype PCB in minimum time.

Our flex PCB manufacturing capabilities allow us to produce top performing flex PCBs.

Our expanded experience enables us to develop custom Rigid-Flex circuit boards for any project. Please view our full feature rigid-flex PCB manufacturing capabilities below.

CPS Tech is an experienced high speed manufacturer that provides reliable, superior-performing high-frequency PCB fabrication services.

CPS Tech is a highly skilled and professional company that can develop and create a thick copper PCB for power electronics applications of the highest quality. We offer thick copper PCBs with the following capabilities.

PCB Assembly

The turnkey design process includes everything from schematic capture to PCB layout and manufacturing (where required). Our learned and experienced team perform all the design and test processes to provide our clients with high-end quality products.

CPS Tech takes your unique PCB design, prepares it for the assembly process, and performs comprehensive testing to ensure your design meets your requirements precisely.

Box Build Assembly

A box build, also known as systems integration, can be anything from a simple PCBA (Printed Circuit Board Assembly) housed in a small enclosure, to a cabinet housing a complex electromechanical system. This includes enclosure fabrication, installation and routing of cable, wire harnesses, installation of sub-assembly and components. CPS Tech can assist you with the following box-build assembly services:

- Specialised & integrated PCBA build box assembly services

- Lead-free box-build assemblies based on client requirements (compliant with RoHS)

- Customized designs

- Zero compromise on quality

- Use of a fabrication facility that is built with state-of-the-art equipment, which allows us to build complex box build assemblies with ease

- Box build integrated assemblies which are IPC 610 compliant

From design to production, CPS Tech offers a range of low-pressure molding options. By injecting specialized adhesives around electronic assemblies, sensitive wires, and connector sealing, we will securely encapsulate your electronics to give a watertight solution. We can add a water-resistant coating, which comes in silicone, polyurethane, and acrylic varieties, once we’ve finished installing the electronic components on your PCB items.

We also offer Low-Pressure Injection Molding is an inexpensive, environmentally friendly process used to encapsulate and protect components like PCBs, sensors, switches, batteries and connectors from the environment.